Strict quality control

Work is checked at all stages of hand-making cigars – cigars that fail the strict quality-control tests will never become Habanos.

Every day the Workshop Manager supervises the work of the cigar rollers. At the same time, supervisors – who are themselves top-grade Torcedores – oversee each brigade of 30 to 40 workers, watching their technique and checking the dimensions of the cigars they are making.

Finished cigars are placed in lidless, wooden boxes. Opened at the front like office out-trays, each mini-rodero is labelled with the Torcedor’s number, the factory name and the date of manufacture.

Afterwards, the mini-roderos are placed inside larger wooden receptacles called roderos, which then go to the quality control department where technicians check the cigars for weight, length, girth, consistency, construction and appearance, particularly examining the tightness of the wrappers and the finish of the caps.

Samples of each Torcedor’s work are regularly taken apart to verify their internal construction and blend. When problems are found, the cigars are deducted from the daily quota – a serious matter for the Torcedores who are paid by piecework.

Among the latest quality control techniques is a machine that checks the draw of the bunch by suction. The test takes place after the bunch has been pressed in the mould and before the wrapper is added. It was first introduced at the end of 2001 and is now used in every factory.

Testing the draw of the bunch by suction before the wrapper is added.

Tasting the result

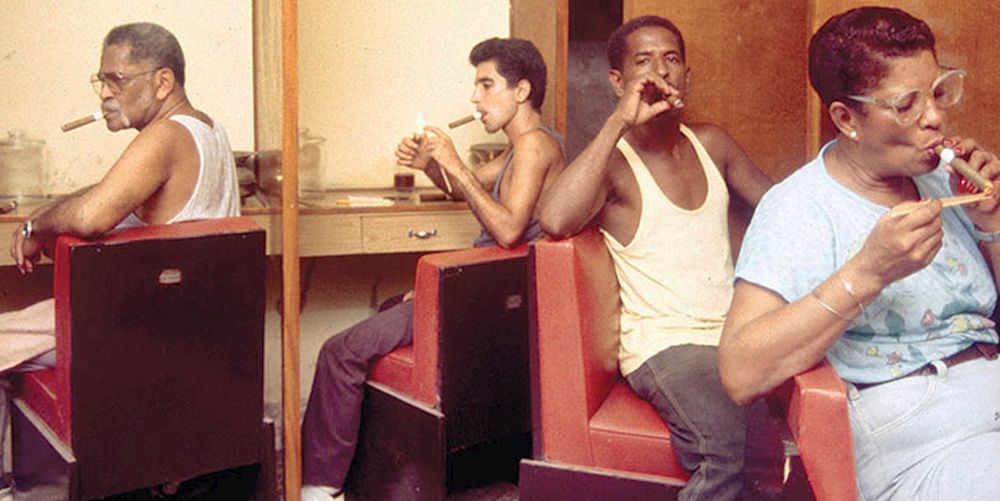

Every factory has its team of cigar tasters – the Catadores – who meet every day to test cigars and score them according to a six-point quality checklist for draw, burn, aroma, flavour, strength and overall quality. Three to five different cigars are tested at each sitting. If any deviation from the normal character of any brand and size is detected, they recommend adjustments to the blend.

The Catadores or tasters regularly smoke the work of each Torcedor in the factory.

The Catadores are the front line of the Comision Nacional de Degustación (National Commission for Tasting) which, as a part of the Tobacco Research Institute, is closely related to the Regulatory Council for the Protected Denomination of Origin (DOP) Habanos. The latter is responsible for the consistency of the blends of all Habanos.

At any time, the Regulatory Council can make spot checks on any of the quality control procedures.

Time to rest

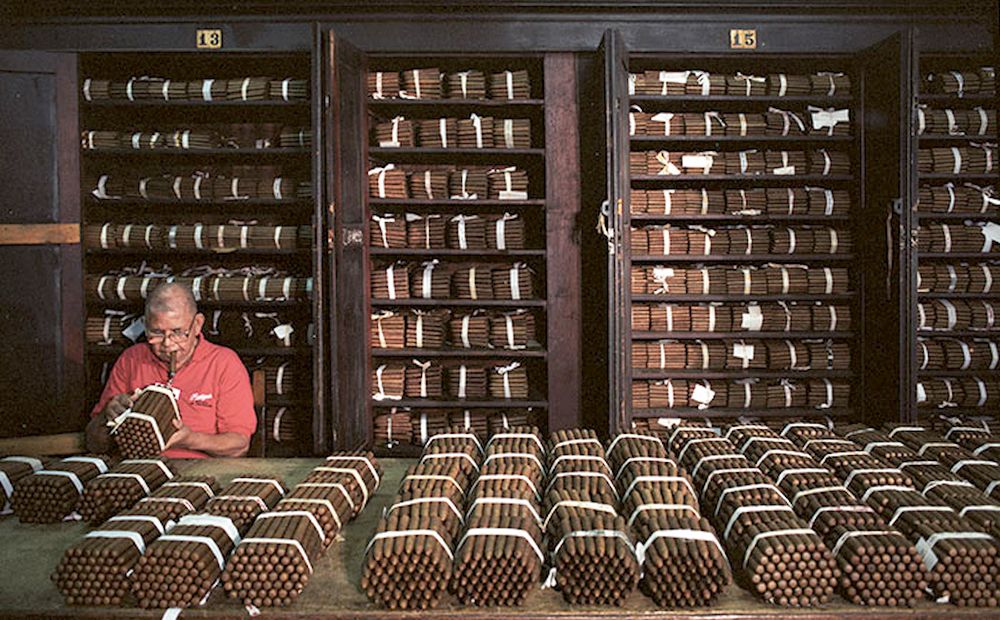

Between making and packing, the cigars are taken to the conditioning room or Escaparate. Here in cedar-lined drawers, they are left to rest while they shed the excess moisture that was gained in the rolling process. After a week, the cigars become smokable, but the longer they stay here the better. Conditions are strictly maintained at between 16 and 18°C and 65 to 70 percent relative humidity, noticeably cooler and drier than the ambient Cuban climate.

The Escaparate is often referred to as the “treasury”. It is here that the true wealth of the factory is stored.

Formerly in the Escaparate Habanos were stored in bundles of 50. Partagas Factory, Escaparate, 2000. La Habana, Cuba.

Source: Habanos

Earlier articles:

Other methods of cigar manufacture

Processing sun-grown leaf for Habano fillers and binders

Shade-grown leaf for Habano wrappers

Nothing lesser than the best leaf for a Habano

Too wet, too dry, infestation issues

The ritual of cutting, lighting and smoking a Habano

The leaves that clothe the body

Cohiba: Fidel Castro’s all-time favourite cigar